Apart from the Linotype machines themselves, the operators had a broad range of accessories available to keep the machine and the matrices in a good condition. The list is too long to mention everything, we only list some interesting devices here.

Companies like Funditor provided alternative ways to clean Linotypes. The device below allowd for a thorough cleaning of the piston pump.

Sources

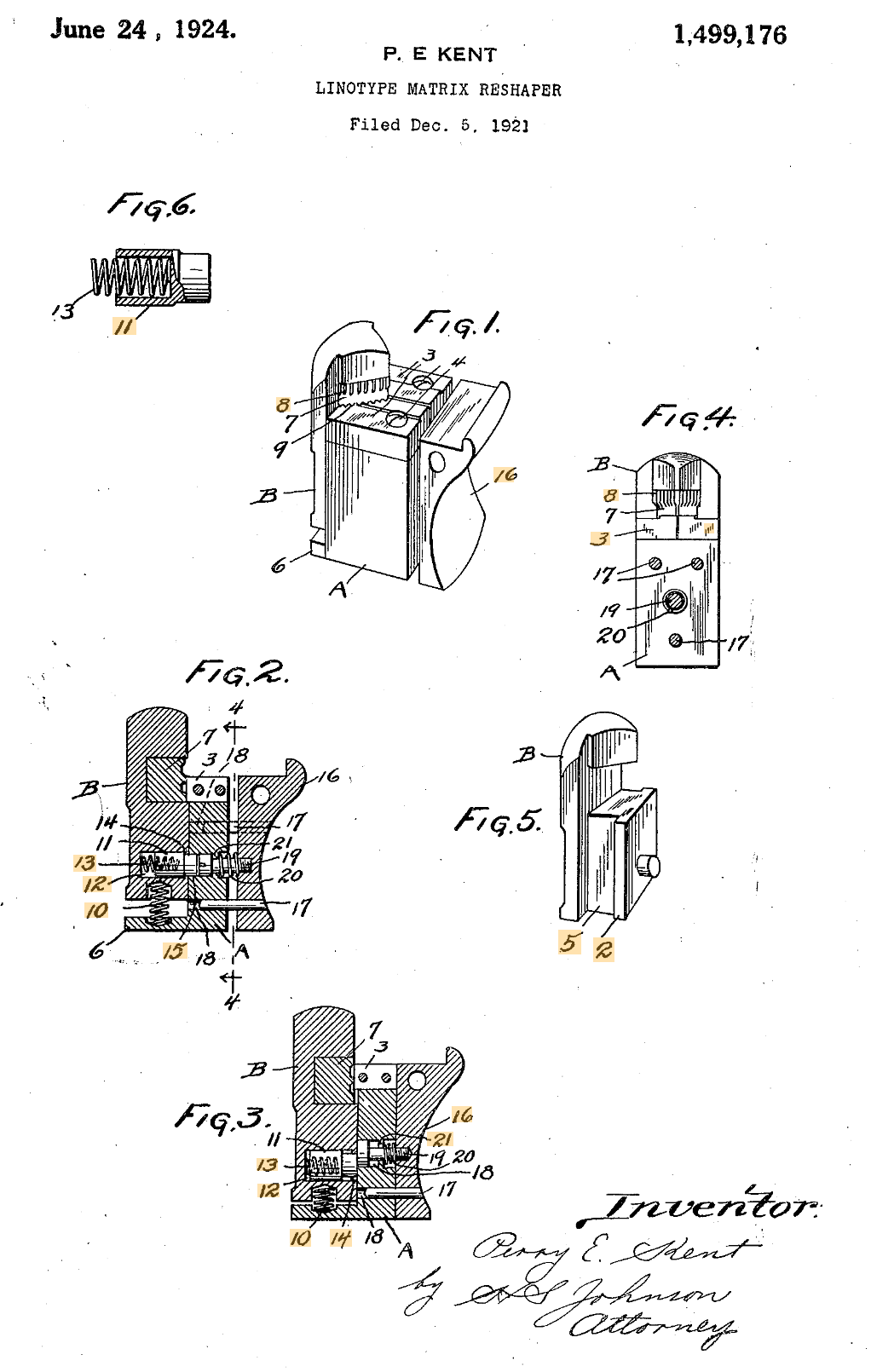

The teeth of the matrices can be damaged easily. Linotype designed the Matrices Reshaper, which could bring bent or damaged teeth back in shape.

Sources

The lugs of the matrices can be damaged easily. Special designed files were able to take of the damage easily, so the matrix would fit again in the machine.

Sources

The Polytype allowed to clean a lot of matrices very fast. While not very thorough, it provided a good job for matrices which were generally well maintained. The machine, as shown in the image and video below, was completely automated. The cleaning product was gasoline.

Sources

The Rocla allowed to clean several matrices in a row for a quick clean. The machine was operated by hand, although it was possible to add a motor (most right one on the image). The cleaning product was gasoline.

Sources

A sawdust matrix cleaning device cleans matrices by moving around. One puts some sawdust in the box, then some matrices, and then some more sawdust. This cleaning device is working very slow, with a maximum of 65 till 75 tours per minute. The slower the box is turning, the better for the matrices. This is to avoid damage to the matrices. It can be attached to a Linotype machine, so this cleaning device is cleaning while an operator is working.

In the recording below, the cleaning device is busy cleaning Ludlow matrices.

Sources

C 2021-2024 Maarten Renckens and other contributors. All rights reserved. All materials on this website are available for non-commercial re-use, as long as the original author is mentioned and a correct reference to this site is added. Thanks!

All materials are considered copyrighted by the author(s) unless otherwise stated. Some materials from other sources are used. If you find materials on this page which you consider not free from copyright, a notification is appreciated.

All collaborations and additional sources are more than welcome. Please contact info@maartenrenckens.com if you have materials that you deem valuable.